In the EHS world, leading indicators help organizations to look ahead and act before safety problems occur. While they were traditionally manually collected and analyzed, digitizing them generates accuracy, speed, and automation in the identification of key signals. And automating the actions triggered by these leading indicators creates an EHS Digital Safety Net across your company based on your data.

Defining leading indicators

Leading indicators are a set of data that show the direction and rate of change for a specific area. Organizations use them to make informed decisions about their business and take actions to prevent problems from occurring. For example, if the number of near misses at a factory is rising, this would be an indicator that something needs to be done. In this case, it might mean more safety training for employees or changes to equipment in use.

The best safety management systems are proactive and predictive. They help organizations identify risks before they occur, then take corrective actions that prevent accidents. To do this effectively, organizations must monitor the state of their safety systems and use leading indicators to identify areas that need attention.

Digitizing Leading Indicators

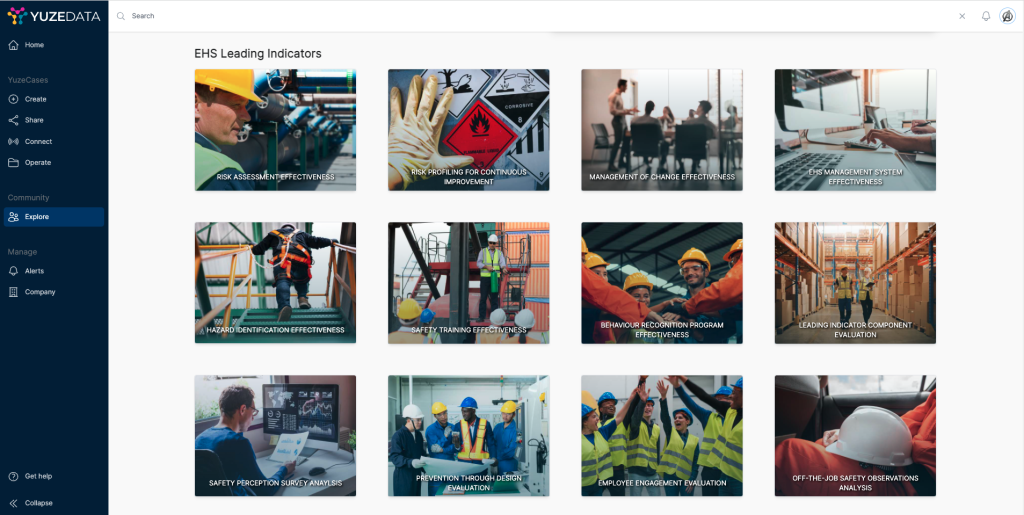

Enterprises have been busy digitizing their systems and processes. They now have many different applications that create the EHS management system footprint that spans all these leading indicators. The data that informs the status of these leading indicators is also spread across all the digital assets of the enterprise. But what’s often missing is an easy way to connect all this disparate data to monitor leading indicators and predict and prevent conditions that could lead to injuries or fatalities.

One solution to this challenge is a template library with pre-built data integration models spanning all the traditional safety-based leading indicators. This makes it easy to connect all the different data sources. And it allows you to set acceptable thresholds that automate alerts, actions, and interventions when the conditions contradict your controls framework. This automates intervention based on escalating leading indicators creating your EHS Digital Safety Net.

Operationalizing Prevention

By digitizing the monitoring and intervention frameworks modeled on top of your data eco-system, you can move from measuring to preventing. It is the shift from analyzing lagging indicators to digitally driving organizational and behavioral change triggered by leading indicators.

Some good examples include:

- Monitor adherence to standard operating procedures through inspections and comparing non-conformance data with training and competence data, triggering audit when compliance and competence levels jointly under-perform; an undesired combination which often leads to incidents

- Monitor near misses as well as safe and unsafe observations reported by employees and management to identify patterns of potentially poorly managed hazards. Actions can be defined for training and coaching intervention

- Track training effectiveness by monitoring, analyzing, and notifying on training goals by individuals, and by organizational hierarchy groups. Compare the data to actual near miss, safety observation, incidents, and CAPA data triggering suggested competence deficiencies

- Evaluate employee engagement by monitoring employee behaviors and actions that demonstrate their extra effort and commitment to ensuring safety.

- Set up benchmarking between sites and operating units and configure notifications to leaders based on lower-performing units where the risk of incidents may be elevated

Leading indicators are only effective if they are integrated into the daily operations of an organization. And if they are connected with other important systems such as maintenance management software, asset management platforms, competence, training systems, HRIS and ERP platforms, and more. Having connectors to all the software platforms that house this leading indicator data, pre-mapped to find the relevant leading indicator content, makes it simple to drive operational performance improvements.

To truly be proactive based on leading indicator data requires the simple connection of all your systems and the deployment of monitoring based on acceptable conditions or performance levels which triggers digitized alerts, action, intervention, and insights.